If you ask the average person on the street where the finest steel originates, chances are they’ll point to Sheffield. For more than a century, Sheffield has been renowned for its steel production. From cutlery to industrial knife blades, this city in South Yorkshire remains at the forefront of the UK’s steel industry. So, what is the history of knives in Sheffield?

Here are the pivotal dates marking the history of knife-making in Sheffield:

- 15th Century - First literary mention of Sheffield steel production.

- 18th Century - Benjamin Huntsman’s ‘crucible steel process’ revolutionised the steel process.

- 19th Century - Henry Bessemer invents what's known as the ‘converter furnace’. These advancements sparked what’s termed as the ‘Bessemer Boom’.

- 20th Century - Post-war decline and then resurgence.

Keep reading to discover more about Sheffield’s illustrious past and promising future with the knife experts at Samuel Staniforth.

Origins of Sheffield’s Steel and Knife Manufacturing

Sheffield's legacy as a hub for steel, knife and cutlery production dates back further than you might imagine. In fact, one of the first literary mentions of Sheffield’s steel production came in Geoffrey Chaucer’s The Canterbury Tales in the early 15th century. However, experts are almost certain that steel production in the area stretches back at least a century further.

Long before the large-scale industrial operations we know today, self-employed craftsmen, known as ‘little mesters’ produced cutlery, tools and knives from start to finish. Working primarily from their own homes, these freelance craftsmen would take the materials they needed from the local forests and hills. This is where Sheffield’s unique geography came into play. It’s close proximity to fast-fl owing rivers, iron ore and the water-powered grinding wheels of Derbyshire offered ideal conditions for the production of tools and utensils. Then, as the trade grew, the little mesters began to rent small workshops. Thus, Sheffield’s steel-making areas began to coalesce.

Subsequently, Sheffield’s steel industry experienced gradual growth, with records indicating merely two operational furnaces as late as the 1730s. Yet, in a matter of years, a pivotal discovery would ignite Sheffield’s steel sector, propelling rapid expansion and thrusting the ‘Steel City’ onto the national and global stage.

The Birth of Crucible Steel

In 1742, manufacturer Benjamin Huntsman’s ‘crucible steel process’ revolutionised steel production, creating tough high-quality steel in larger batches than ever before. The crucible steel process involved the use of coking coal to achieve furnace temperatures high enough to dissolve iron. Huntsman’s method incorporated blister steel instead of direct conversion from cast iron.

This innovation enabled the complete melting of steel, facilitating its pouring into casts and unlocking a multitude of new steel applications.

Huntsman’s process moved Sheffield from a township into a leading European industrial city, with the following century seeing its annual steel production explode from 200 tonnes to 80,00 tonnes, nearly half of Europe’s total production.

Additional Advancements

As is often the case in bustling cities which are growing, innovation triggers more innovation. In 1856, Henry Bessemer invented what was known as the ‘converter furnace’ . The Bessemer process offered a relatively inexpensive way of mass-producing steel from molten pig iron. What made the process so valuable was its ability to remove impurities from the iron via oxidation, with air being blown through the molten iron.

Thanks to this breakthrough, Sheffield’s steel output surged, supplying refined steel for railway components, armour plating and construction. Bessemer’s invention coincided with the emergence of ‘Sheffield Plate’ , pioneered by Thomas Boulsover . This technique involved fusing silver onto copper to produce premium silver plating.

Made In Sheffield: A History of Knife Making Another advancement came from John Brown, Sheffield’s first steelmaker to be knighted. After taking the first Bessemer steel licence in 1860, Brown devised a rolling method for armour plating, and within a decade, his steel was utilised in three-quarters of the Royal Navy’s armour-plated ships.

Sheffield Knives Going Global

These advancements collectively sparked what was termed the ‘Bessemer Boom’ , a phase in which Sheffield emerged as a primary source of steel for vast regions across the globe. Spotlighting this significance on the world stage, it’s worth noting that in 1871, the United States imported over three times the amount of rail track from Sheffield compared to its domestic production.

During this period, Sheffield’s steelmakers continued to innovate, with the first recorded use of stainless steel for cutlery. In 1912, Sheffield-based chemist Harry Brearley discovered ‘rustless steel’, now known as stainless steel. You might be surprised to learn that these innovations took place in Portland Works, which still houses cutlery makers to this day. In fact, we currently work closely with Stuart Mitchell Knives, a family-run business that specialises in the creation of bespoke custom knives.

12 years later, Dr W. H. Hatfield, from the same laboratory, created ‘18/8’, a common form of stainless steel which is 18% chromium and 8% nickel, making it resistant to corrosion and oxidation.

During both World Wars, Sheffield was integral in arming the military, providing raw materials for ships, planes and other armaments. With the men of the city away fighting, the women took over the steelworks, including critical munition production lines. This was commemorated by the ‘Women of Steel’ statue in Sheffield’s centre, unveiled in 2016.

Industrial Challenges & Resilience

Sadly, as with many other industrial cities across the UK, the post-war period saw the beginning of a decline. As a result of waning demand, competition from other countries and a combination of recession and infl ation, Sheffield saw many furnaces close and significant numbers of redundancies amongst the city’s steel-making workforce. In the 1980s, Sheffield lost more than 50,000 steel and engineering jobs.

Despite facing a downturn after the war, Sheffield remained a centre of innovation in steel and knife manufacturing. In fact, during the 1960s, ‘70s and ‘80s, professors F.B. Pickering and T. Gladman conducted pioneering research crucial to the advancement of modern high-strength, low-alloy steels.

By the 20th century, Sheffield’s economic fortunes began to rebound, with numerous new-specialist, high-end steel and knife manufacturers reasserting the city’s presence on the global stage.

Revival & Craftsmanship

Today, Sheffield is home to a series of specialist steel producers and knife manufacturers. As of 2016, the steel industry employs around 2,600 people and focuses on specialist trade, with many craftsmen working in smaller workshops and producing bespoke goods.

Sheffield’s knife heritage is maintained across the city by manufacturers, fabricators and craftsmen of all backgrounds, united by a shared commitment to quality and prestige that has bound the city together for centuries.

History of Cutlery In Sheffield

Due to the wide availability of nearby raw materials such as iron ore, coal, charcoal and stone, Sheffield has always been famous for its metalworking and cutlery production. Sheffield boasts another advantage: its proximity to several fast-fl owing rivers, providing a ready source of wood and charcoal to fuel machinery. In Sheffield’s terminology, ‘cutlery’ includes ‘that what cuts’, such as knives and scissors’.

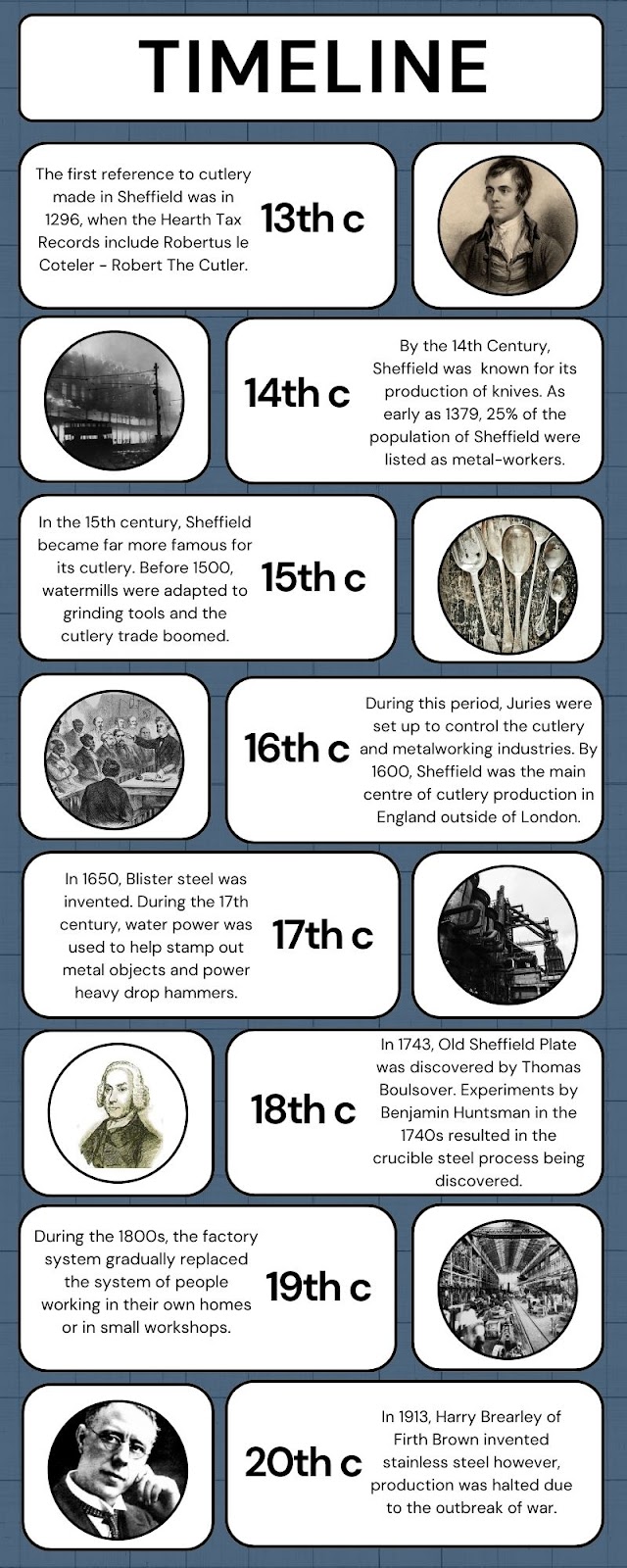

Let’s take a closer look at our timeline which outlines the history of cutlery in Sheffield

History of Samuel Staniforth

So, how does our history at Samuel Staniforth fit into the timeline of cutlery and knife production in Sheffield?

Established in 1864, we are manufacturers of The Smithfield range of knives and have over 100 years of experience in the production of quality forged cutlery for the professional user.

Born in the year 1840, Samuel Staniforth opened the company in 1864. As stated by a Sheffield directory in 1871, Staniforth was listed at No.49 Carver Street in Sheffield as a manufacturer of fancy pens, pocket knives, scales, blades and springs. Forged blades became Staniforth’s speciality and the company soon gained a reputation for consistency and high quality.

Staniforth wasted no time in installing machinery for blanking knife blades from steel sheets, enhancing the factory’s capabilities and ensuring a broader product range. The company’s focus shifted to crafting ‘fancy shape carvers, shell blades and forks of every description.’

Although Staniforth retired in 1894, his legacy endured. Thanks to his groundwork, the company seamlessly transitioned into manufacturing various knife blades. By 1940, it had expanded its repertoire to include trade and military knives, now renowned worldwide. Staniforth paved the way for versatility, a path the company has embraced to adapt from its competitors and become the progressive company it is today.

Staniforth’s company continued to manufacture knife blades, initially under the management of T Merrill Hughes and W. Marshall. The company was then bought by the Osborne family, who owned Heathcotes.

This is where our journey with the business begins. Samuel Staniforth Ltd was purchased from the Osborne family by Chris Hopkinson and was relocated out of the City Centre to Halfway, Sheffield. With over 20 workers and using both French and English Steel, the company continues to make knives for butchers, chefs, the military and hunters.

As a Sheffield-based business, we’re proud to embody the global reputation the city has for high standards and strong manufacturing pedigree. Our commitment to producing quality professional knives remains at the heart of everything we do at Samuel Staniforth.

If you’re hoping to add a piece of Sheffield’s history to your kitchen, take a look at our range of quality knives. Our Sheffield steel knives combine traditional materials sourced in Sheffield with the most modern new technology production methods. In particular, our Heritage range carries the Made In Sheffield mark, which guarantees superior craftsmanship and quality. Made from SF 100 Sheffield stainless steel, hardened to 61 HRC (Rockwell), creates a knife with ultimate durability, ease of sharpening and edge retention.

Get in touch with our knife experts today to find out more.

History of Knife Making FAQs

What is Sheffield’s Connection to Knife Making?

Sheffield has a long-standing tradition of knife making which dates back centuries. The city became renowned for its high-quality steel production and skilled craftsmen, establishing itself as a leading centre for knife manufacturing.

When Did Knife Making Begin in Sheffield?

Sheffield’s knife-making roots date back to the Middle Ages. However, it thoroughly flourished during the 18th and 19th centuries when advancements in steel production and manufacturing techniques led to increased output and quality.

What Types of Knives Were Traditionally Produced in Sheffield?

Sheffield was known for producing a wide range of knives, including pocket knives, hunting knives, kitchen knives, and specialised blades for various industries such as agriculture, cutlery, and weaponry.

How Did the Industrial Revolution Impact Knife Making in Sheffield?

The Industrial Revolution brought significant advancements to the knife-making industry in Sheffield. The introduction of mechanised processes and mass production techniques revolutionised manufacturing, leading to increased efficiency and output.

What Led to the Decline of Knife Making in Sheffield?

The decline of knife making in Sheffield can be attributed to various factors, including:

- Changes in consumer preferences

- Competition from international markets

- Shifts in manufacturing technology

However, you’ll be pleased to know that the industry has adapted and evolved to remain relevant in the modern era.

How Does Sheffield's Knife-Making Industry Preserve its Heritage Today?

Today, Sheffield's knife-making industry continues to honour its heritage by blending traditional craftsmanship with modern techniques. Many companies in Sheffield focus on producing high-quality, handcrafted knives while also preserving the city's rich history through museums, exhibitions and educational programs.